Roll Conveyor Belt Textile Inkjet Digital Disperse Ink Printing Direct to Garment Printer

Overview The print media does not go astray 06 Leadshine brushless servo motor Strictly control high mechanical precisio

Send your inquiryDESCRIPTION

OverviewBasic Info.

| Model NO. | BC-1904E-PMP |

| Automatic Grade | Automatic |

| Printing Interface | USB3.0 |

| Printing Speed | 7.5CPI |

| System Supported | Windowsxp64 |

| Color | C M Y K |

| Print Media | Fabric |

| Ink Capacity | 4*30L |

| Rip Software | Maintop/Wasatch/Neostampa(Optional) |

| Ink Type | Disperse Ink |

| Printheads Number | 4/6/8 |

| Print Width | 1800mm |

| Print Head | Epn I3200/4720 |

| Product Name | Direct to Fabric Printer |

| Transport Package | Wooden Box |

| Specification | 320KGS |

| Trademark | PO-TRY / Customized |

| Origin | China |

| Production Capacity | 5000set/Month |

Product Description

The print media does not go astray06 Leadshine brushless servo motor

Strictly control high mechanical precision printing07 Secondary Negative Pressure Ink Supply System

Smoothly printing and protect the print heads

| Specifications&technical Data | ||

| Model number | BC-1904-DMP | BC-1908-DMP |

| Print head | EPSON i3200/4720 | |

| Number of Print heads | 4 | 8 |

| Print resolution/speed | 4Pass 360*2400DPI 75m²/H | 4Pass 360*1200DPI 150m²/H |

| 6Pass720*1800DPI50m²/H | 6Pass 360*1200DPI 100m²/H | |

| Print Width | 1800mm | |

| Ink Type | Disperse ink | |

| Ink Capacity | 4*5L | |

| Color | K C M Y | |

| Max Medium Weight | 50KGS | |

| RIP software | Maintop 6.0 / Wasatch / Neostampa (optional) | |

| Computer System | Win 7 64 bit / Win 10 64bit | |

| Computer configuration Reference | Hard disk: 500G / 1T, ATI independent video card, Gigabit network card, 8G memory, Intel quad-core i5 or i7 CPU processor. :500G/1T,ATI,,8G,i5i7CPU | |

| File format | TIF | |

| Work environment | Temperature: 15 -28ºC, Humidity: 40%-60%. | |

| Drying system | Automatic surface drying,heating and collecting belt heating(External Independent Drying System Optional) ,() | |

| Water Washing system | Self Washing and Drying System of The Conduction Belt | |

| Rectifying System | Self correcting system for conduction belt | |

| Power Supply | AC220V ± 10%. AC380 ± 10%,50/60 ± 1Hz | |

| Max Power(Watt) | 5000W / 8000W, 220V/380V | |

| Advanced Feature | Automatic cleaning; Automatic Alarming System for Empty Ink Supply; Automatic flash spray moisturizing function. ;;. | |

| Machine Size | L3180mm*W2000mm*H1320mm | |

| Outer Box Size | L3400mm*W2200*H1550mm | |

| Net Weight / Gross Weight | 1300KGS / 1600KGS | |

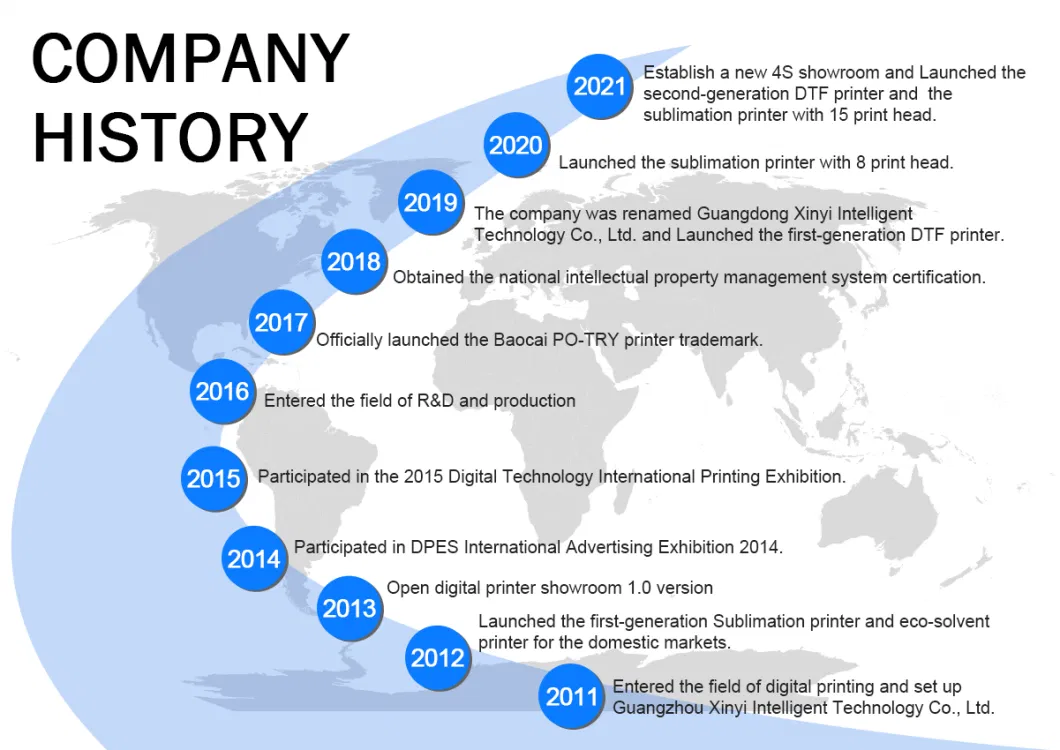

Company Profile

As a professional Fabric Digital Printing Machine Manufacturer, PO-TRY focuses on providing customers with a professional printing solution that is mature, more efficient, and stable.

PO-TRY's products are oriented to both household and commercial markets in the digital printer field. Our main products included the Sublimation printer, DTF printer, DTG printer, textile printer, leather printer, printing inks, and printing consumables.

Our products have necessary patents in terms of appearance and functions, ensuring that our customers are more advantaged in the local market and not interfered with by imitators.

PO-TRY has a wealth of industry experience in fabric digital printing, values feedback from every customer, and are constantly committed to expanding product functions and improving product performance. We have our own R&D team and after-sales team to support any technical problems.

ODM and OEM services are available. By carrying out comprehensive dealer support programs, we are devoted to assisting our customers with their growth in sales.

Certifications

Exhibition

We have participated in many Textile Digital Printing Exhibitions and achieved excellent results.

At each exhibition, we would bring PO-TRY's latest products and solutions, demonstrating the product functions and usage to the customers.We believe that communicating with customers face-to-face is the most effective way of communication, which not only allows customers to feel our professionalism better but also allows us to get suggestions and ideas from them more accurately.Many thanks to every customer who has visited our booth. Thank you for your trust and recognition, which gave us the confidence to develop better products.